"We think about a product and handle all of its aspects"

Article in https://www.themarker.com

Agam Kedem Levy, in collaboration with “From Idea to Product”

From an international pizza brand to government offices: Irit Farjon Roldao, founder of “From Idea to Product,” a company specializing in product design, explains the challenges brought about by the technological revolution and how customers can be made to feel comfortable from the very first encounter with a product

“We look at products and develop them in a holistic way,” begins Irit Farjon Roldao, who has been the head of “From Idea to Product” since 1995 – which is actually a kind of link that connects engineering and technological activity – and the user experience of the end consumer.

Irit Farjon Roldao, head of “From Idea to Product”. Photography: Hila Gvir Photography Studio.

“The role of the product designer is to explore all the intricacies of the production and development processes. Already during product characterization we help customers see all the aspects,” adds Farjon Roldao, a graduate of Industrial Design at the Bezalel Academy of Art and Design, winner of the “Glass” award for design, and a graduate of the Generals project for production processes and product planning at Migdal Tefen and medical innovation at Tel Aviv University.

The product, the customer and the target market

“From Idea to Product” currently operates in two locations: in the Tefen Industrial Park in the Galilee and in Azrieli Towers in Tel Aviv. She works with many of the largest companies in the market, alongside accompanying young start-up companies and private entrepreneurs. “We know how to manage an entire project from A to Z or integrate into the client’s development teams,” says Farjon Roldao.

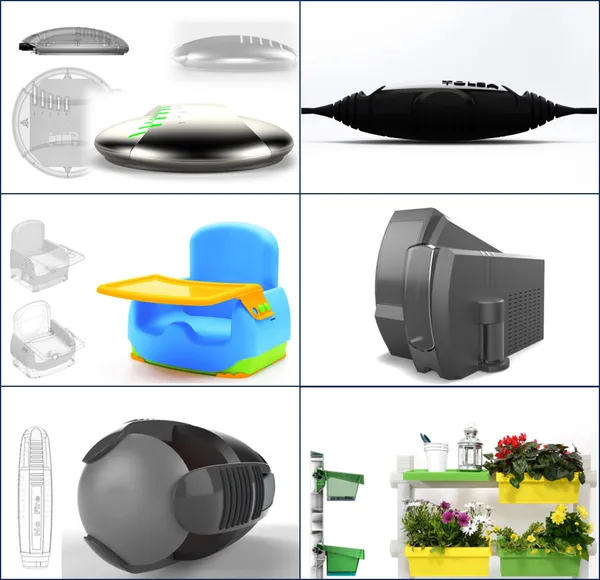

From idea to product, industrial design, engineering planning, building a prototype, preparing a product portfolio, serial production Irit Farjon

Products that she designed “From Idea to Product” are currently marketed by leading international brands such as Kimberly-Clark and Pizza Hut. In addition, “From Idea to Product” serves as a supplier to the Ministry of Defense in the field of “innovation” and as a consultant for the Chamber of Commerce and the Ministry of Science and Innovation. Some of her designs were even featured at exhibitions in Israel and around the world. “From Idea to Product” specializes in industrial design, engineering design, human engineering and user experience, building prototypes – and preparing a product portfolio for production. “We serve as an innovation body for customers who wish to expand their product portfolio or improve the existing one,” explains Farjon Roldao. “When it comes to working with entrepreneurs or start-ups, our studio is a one-stop shop. In cases of new technological development, we help apply for state budgets and private investments. When working with large companies that operate established development departments, we are often a complementary body that works with the department. Our role in the development process starts from the earliest stages.”

“We know how to manage an entire project from A to Z”

According to Farjon Roldao, “the designer’s point of view broadens the product profile to areas such as human engineering, branding, user experience, and more. These issues arise already in the characterization phase and are dealt with during development. This is the way to prevent conflicts and wasted time. If the design is handled after the product is planned, sometimes It’s already too late to ‘reopen’ the entire design, then the danger is that the product on the shelf will look like a compromise. Studies show that good design increases sales of a product by 17 percent. The initial encounter with the product is critical.”

She adds that “there is no point in developing a product that already exists on the market or is patent protected. Therefore, even before we draw lines for initial sketches, we interview the customer, study the idea in-depth and recommend conducting a market survey and a patent survey in order to test the product’s feasibility.”

After the decision is made to proceed with product development, what role does “From Idea to Product” play?

We fine-tune the product and the customer’s characterization and the target market, plan and design the product. At these stages the customer is very involved. He sees several options and chooses his preferred direction to continue. We can present our ideas using computer simulations, or with the help of physical models that we produce in our studio in Tefen, China or Portugal. Illustrating with a physical model is preferable in cases where the product is related to the body – worn, held or bandaged. For example, we recently developed a device for audiological testing for two Israeli doctors. In this type of project we test our ideas with the help of a physical prototype. In this case, a hearing aid worn on the head.”

To break the technological boundaries

In “From Idea to Product” we face a series of challenges throughout all stages of the development and design process. Farjon Roldao points out that “we think about a product and handle all of its aspects,” explaining that one of the main complexities is the interface between man and machine. In other words, ease of use and the human engineering that is reflected in the encounter between product and user: “The customer deserves convenience – already in his first meeting with the physical product or with the software and application. Today customers are completely accustomed to intuitive use of products – without learning processes. This is a standard requirement in the market. That is why we strive for products that the customer completely understands intuitively.”

What current trends are noticeable today in the field?

The world of technology world is developing at a crazy pace, on a ‘blink-you-missed-it’ level. The boundaries between hardware and software are more blurred than ever. Sensors in the product detect the user when he approaches – and the product contacts the user. The relationship between man and machine has become closer than ever. A machine checks the pantry for us and orders what is missing or even reacts to our mood. This is the great revolution that is happening today in the field of product design. Projects from the world of IoT or smart products are an excellent example of this change.”

How does the team of “From Idea to Product” make sure to prepare in advance for the big task of every manufacturer – industrial production?

Our design ‘knows’ how the product comes out of the mold, how it will be CNC cut or bent. There are no surprises in our work process. In cases where we integrate into a development team, the client’s product planners receive ready-made files from us, so they can continue working on the file. Our strength is in design, planning and human engineering for products manufactured in large series, in different production technologies and with various materials such as plastic, tin and soft materials.”

In conclusion, Farjon Roldao points to notable projects that she led “From Idea to Product”: “Recently, we provided a unique solution to the IFEEL company’s smart home products that are sold around the world. Our solution included the design of the physical product alongside the design of the interaction between it and the user through the software – the user experience. Another example is the development we did for the Caesarstone company. Beyond the design of the product and the application, we held a joint brainstorming session to test the product limits: what can be developed now and what technological limits can we break through in the future. Collecting and processing the data allows the product developers to regularly refine the product. This is an unbelievable technological capability.”